We are Manufacturer, Supplier, Exporter of Wafer Check Valves, Check Valves and our set up is situated in Belgaum, Karnataka, India. P. S. wafer design Check Valves (NRV) are especially designed for low Pressure Applications, where min pressure drop is desired.

The Non Return Valve Wafer Swing Type, offered by us, is widely demanded in the market as there is no alternative available in terms of quality and performance. Premium quality raw materials are used in the manufacturing of the Non Return Valve Wafer Swing Type that ensures high durability, tensile strength and resistivity to adverse conditions.

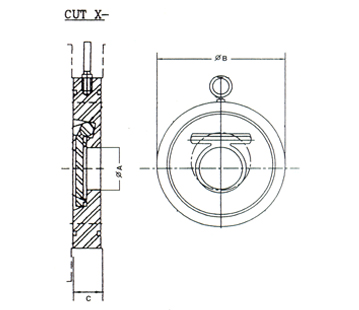

| Size | A | B | C | WT. KG. | Opening | PR. |

| mm | ||||||

| 40 | 22 | 96 | 16 | 1.5 | 40 | 45 |

| 50 | 26 | 100 | 16 | 1.7 | 41 | 48 |

| 65 | 38 | 130 | 16 | 2.5 | 56 | 50 |

| 80 | 48 | 145 | 16 | 3 | 62 | 50 |

| 100 | 73 | 165 | 16 | 3.5 | 80 | 60 |

| 125 | 96 | 195 | 18 | 5 | 103 | 63 |

| 150 | 116 | 219 | 21 | 7 | 121 | 80 |

| 200 | 142 | 274 | 31 | 13 | 155 | 90 |

| 250 | 190 | 329 | 31 | 17 | 203 | 135 |

| 300 | 218 | 379 | 40 | 29 | 230 | 155 |

| 350 | 265 | 440 | 42 | 45 | 271 | 160 |

| 400 | 306 | 491 | 53 | 65 | 310 | 170 |

| 450 | 358 | 539 | 53 | 80 | 362 | 185 |

| 500 | 408 | 594 | 63 | 120 | 401 | - |

| 600 | 485 | 697 | 72 | 180 | 481 | - |

40 - to 1000 mm.

Largely used in Sugar, Distilleries; Cement; All chemical & Petrochemical Industries, Thermal power stations, Air conditioning & Oil, Air, Gas & Water, plants, Fire protection systems.

Graded Cast Iron, S.G.I Iron, Cast Steel WCB Grade Complete Stainless Steel; AISI 304, 316, & Low Carbon Steel

EPDM, Nitrile, Neoprene, Silicon, Viton & PTEF Valves can also be provided with Telfon rubber lining. Replaceable 'o' ring placed in dove tail groove of disc & Body.

Suitable for Vertical & Horizontal

Suitable for mounting between various flange Stds. ASA 150-300, DIN & IS Stds. When installing a check Valve on the delivery side, do not assemble it directly on to the pump flange or on to a following bend or elbow. The valve may be fitted at a distance of 7 to 10 times the nominal width, from the beginning of the stabilised distance.

6-100 kg/cm2

Minus 60 deg. C. to plus 400 deg. C.