These valves are well known for its high rigidity and consumption obstruction. Accessible in assortment of sizes, these Pulp Valves discover application in different areas like military, business, transportation parts.

We are counted amongst the reputable Pulp Stock Valve (Knife Gate) manufacturers in India. Customers from every nook and corner of India are placing bulk orders for the Pulp Stock Valve (Knife Gate) as no alternative is available in terms of quality and performance. Buyers are also eased with the availability of the products in varied sizes and dimensions as required by the application area.

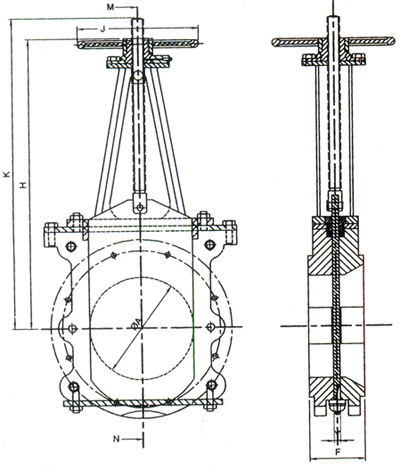

| Valve | A | F | H | J | K | TEST & WORKING PRESSURE | |||||

| mm | inch | Body | Working Pr. | Working Pr. | |||||||

| 50 | 2" | 50 | 60 | 290 | 175 | 370 | 10Kg / cm2 | 6Kg / Cm2 | 120o | ||

| 65 | 2.5" | 65 | 62 | 306 | 175 | 400 | 10 | " | 6 | " | 120o |

| 80 | 3" | 80 | 62 | 335 | 175 | 445 | 10 | " | 6 | " | " |

| 100 | 4" | 100 | 64 | 352 | 200 | 480 | 6 | " | 6 | " | " |

| 125 | 5" | 125 | 64 | 393 | 200 | 540 | 6 | " | 4 | " | " |

| 150 | 6" | 150 | 68 | 456 | 248 | 626 | 6 | " | 4 | " | " |

| 200 | 8" | 200 | 70 | 535 | 305 | 760 | 4 | " | 4 | " | " |

| 250 | 10" | 250 | 76 | 652 | 305 | 936 | 4 | " | 2 | " | " |

| 300 | 12" | 300 | 80 | 727 | 305 | 1057 | 4 | " | 2 | " | " |

| 350 | 14" | 350 | 96 | 832 | 430 | 1225 | 4 | " | 2 | " | " |

| 400 | 16" | 400 | 100 | 922 | 430 | 1362 | 4 | " | 2 | " | " |

| 500 | 20" | 500 | 114 | 1075 | 430 | 1620 | 4 | " | 2 | " | " |

| SR. NO. | PART NAME | MAT |

| 1. | EYE BOLT FOR P. NO. 3 | M. S. |

| 2. | HEX. NUT FOR BOLTS | M. S. |

| 3. | SCOUR PLATE | M. S. |

| 4. | PACKING FOR S. PLATE | Rubber |

| 5. | CAP SCREW | M. S. |

| 6. | PACKING | Rubber |

| 7. | PLANCE FACE | CI |

| 8. | GUIDE FACE | CI |

| SR. NO. | PART NAME | MAT |

| 9. | GLAND PACKING | Rubber |

| 10. | HEX. BOLT | M. S. |

| 11. | EYE BOLT FOR GLAND | M. S. |

| 12. | RISING SPINDLE | 304 |

| 13. | YOKE | M. S. |

| 14. | PIN | M. S. |

| 15. | COTTER | P. |

| 16. | GLAND | M. S. |

| SR. NO. | PART NAME | MAT |

| 17. | GATE | SS304 |

| 18. | NUT COVER | CI |

| 19. | NUT | CI |

| 20. | GREASE NIPPLE | M. S. |

| 21. | HAND WHEEL | CI |

| 22. | GRUB SCREW | M. S. |

| Const. | Body | Yoke | Cover | H. Wheel | Gate | Scour | Spindle | Gland |

| 1 | C. I | M. S. | C. I. | C. I. | SS 304 | M. S. | AISI304 | M. S. |

| 2 | SS 304 | M. S. | C. I. | C. I. | SS 316 | AISI304 | AISI316 | AISI304 |

| 3 | SS 316 | M. S. | C. I. | C. I. | SS 410 | CF | 410 | CF 12 |

| 4 | CF 8M | M. S. | C. I. | C. I. | SS 316 | CF 12M | En8 | CF 12M |

Accurately Machined split body to insure tight shut off & to eleminate accumulation of pulp in body.

The fabricated, angular Super Steel structure yoke stands up under the most difficult operating conditions. Extra strength are built in to withstand unusual stressess.

A heavily designed SGNI nut to provide easy operation and longer life under any type of corrosive conditions.

Stainless Steel spindle for extra corrosive resistance with ACME threads provides easy operation & longlife.

Stainless steel knifedge thick gate resist damage and allow higher drops the beleved knife edge pushes aside or cuts through solids in flow. 5.1 Seating & Guide : Accurately machined guide ways are provided for positive seating of gate. Rugged guides provided on either side of valve to provide proper support in the movement of gate.

A inttrile gland rubber fitted in the slot to prevent leakage.

A M.S. Fabricated Gland is provided to hold the rubber.

A M.S. Plate with Rubber packing is provided for easy on line maintenance of the valve.

A properly designed CI handwheel is provided for easy operation.