We are Manufacturer, Supplier, Exporter of Butterfly Valves, Industrial Butterfly Valves and our set up is situated in Belgaum, Karnataka, India.

PS-MAXFLOW VALVE are reckoned as one of the reliable Butterfly Valves , Sleeve Lined Wafer Type centric disc type, manufacturers in India. The use of premium quality raw materials in the manufacturing of the butterfly valves ensures high durability, tensile strength and resistivity to adverse conditions. The products are also available in varied sizes and dimensions as provided by the potential buyers.

PS-MAXFLOW VALVE are reckoned as one of the reliable Butterfly Valves , Sleeve Lined Wafer Type centric disc type, manufacturers in India. The use of premium quality raw materials in the manufacturing of the butterfly valves ensures high durability, tensile strength and resistivity to adverse conditions. The products are also available in varied sizes and dimensions as provided by the potential buyers.

PS-MAXFLOW VALVES ARE specialize in proving Butterfly Valves that are M.S. Fabricated for Higher Sizes Double Eccentric Type. The features like high durability and resistivity to adverse conditions has attracted various industrial sectors to place bulk orders. We are also renowned as one of the eminent butterfly valves manufacturers, based in India.

Ps-maxflow Make Butterfly Valve Are Centric Disc Type ,three Piece Design, Tight Shut-off Valves Operated With Hand Lever With Notch Plate Arrangement For 10degree Intervals.

Two piece Design up to 300 mm size & Single piece for sizes above 350 mm, ensuring Max, flow & trouble free replacement of parts.

Replaceable , completely lining the body throughout the fluid contact part, assuring tightness from both sides of the disc & at the stem passage. Seat is provided with integral "0" Ring thus eliminating the use of gaskets between flanges.

Polyacetal bush with Two "0" rings acts as & bearing, thus further easening opening & closing of valve.

Suitable for Throtting, Regulating on/off service for practically all mediums of flow ; Water, & Chemically treated water, Gases & Vapours, Air, Dust like products, Liquids containing suspended solids, Food, oils, Milk & Food products, Aggressive chemicals, Acids & Crude Oil, & Petrochemical products, Refineries, Fertilisers & Ash handling

One piece Investment Cast for sizes up to 100 mm ; & Two piece for sizes 125 mm & above ; Centrically Located to withstand & cope great strain & increased torque.

Two Lubricated Bearings Bush at the top & bottom ensures low operating torque, making the valves completely maintenance free.

P.S. Sleeve lined Wafer Design Butterfly valves Manufactured as per ISO-5752 short & DIN Stds. Valves as per API 609 ; BS-5155, 3952

| TEST PRESSURES Kg / cm2 |

SIZE MM | BODY | SEAT | PNEUMATIC TEST |

| 25 - 300 | 15 | 10 | 6.5 | |

| 350 - 600 | 14 | 6 | - | |

| 650 - 1000 | 10 | 5 | - |

Suitable for fitment between flanges as per IS-1538, BS, ANSI B-16.5 ; Class 150 ibs, DIN PN 10/16 ; API or any other std.

Graded CI, CS, CF8, CF8M ; Alloy 20 ; Low Carbon Steel

Food graded EPDM ; Neoprene : Silicon ; Viton, & PTFE

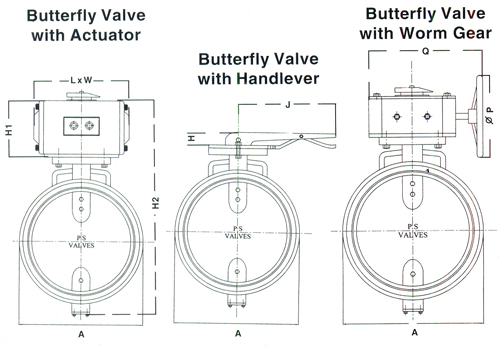

Hand lever for ON / OFF; Notch Disc with lever for Throttling, Worm gears, Pneumatic Actuators both rotary & linear, single & double acting & Electric actuators. Complete system with solenoid valves, limit switches, positioners with Control panel can be tailor-made.

| DN | A | B | C | D | H | J Min |

TOP MOUNTING FLANGES | P | Q Max |

Bare Wt. Kgs. |

LxW | H1 | H2 | ||

| PCD | N | d | |||||||||||||

| 25 | 71 | 56 | 10 | 28 | 25 | 265 | 43 | 4 | 7 | - | - | 1.5 | 130x78 | 78 | 205 |

| 40 | 91 | 56 | 10 | 32 | 25 | 265 | 43 | 4 | 7 | - | - | 2.5 | 130x78 | 78 | 345 |

| 50 | 106 | 101 | 14 | 42 | 30 | 265 | 82 | 4 | 9 | 220 | 285 | 3.8 | 130x78 | 78 | 345 |

| 65 | 116 | 101 | 14 | 47 | 30 | 265 | 82 | 4 | 9 | 220 | 285 | 4.8 | 188x108 | 160 | 415 |

| 80 | 141 | 101 | 14 | 47 | 30 | 265 | 82 | 4 | 9 | 220 | 285 | 6.0 | 188x108 | 160 | 430 |

| 100 | 162 | 101 | 16 | 53 | 30 | 265 | 82 | 4 | 9 | 220 | 285 | 6.5 | 188x108 | 160 | 430 |

| 125 | 192 | 101 | 19 | 57 | 30 | 265 | 82 | 4 | 9 | 220 | 285 | 8.0 | 188x108 | 160 | 480 |

| 150 | 218 | 101 | 19 | 57 | 30 | 265 | 82 | 4 | 9 | 220 | 285 | 10.5 | 276x157 | 162 | 570 |

| 200 | 271 | 150 | 22 | 59 | 39 | 300 | 125 | 4 | 13 | 220 | 285 | 19 | 276x157 | 162 | 630 |

| 250 | 328 | 150 | 30 | 69 | 39 | 400 | 125 | 4 | 13 | 315 | 335 | 23 | 356x214 | 222 | 745 |

| 300 | 375 | 150 | 30 | 79 | 39 | 400 | 125 | 4 | 13 | 315 | 335 | 46 | 356x214 | 222 | 860 |

| 350 | 438 | 150 | 30 | 79 | 50 | 125 | 4 | 17 | 365 | 465 | 56 | 356x214 | 222 | 895 | |

| 400 | 481 | 150 | 40 | 101 | 60 | 125 | 4 | 17 | 365 | 465 | 85 | 400x276 | 285 | 1060 | |

| 450 | 542 | 201 | 50 | 114 | 60 | 165 | 4 | 22 | 365 | 465 | 95 | 400x276 | 285 | 1225 | |

| 500 | 598 | 201 | 50 | 127 | 60 | 165 | 4 | 22 | 450 | 465 | 140 | 551x355 | 355 | 1300 | |

| 600 | 712 | 309 | 60 | 149 | 90 | 254 | 8 | 22 | 525 | 475 | 180 | - | - | - | |

| 700 | 834 | 309 | 60 | 170 | 90 | 254 | 8 | 22 | - | - | - | - | - | - | |

| 750 | 880 | 329 | 60 | 170 | 90 | 254 | 8 | 22 | - | - | - | - | - | - | |

| 800 | 945 | 320 | 75 | 189 | 120 | 254 | 8 | 22 | - | - | - | - | - | - | |

| 900 | 1040 | 329 | 75 | 205 | 120 | 298 | 8 | 22 | - | - | - | - | - | - | |

| 1000 | 1180 | 389 | 120 | 216 | 153 | 298 | 8 | 22 | - | - | - | - | - | - | |